AFB Flaring & Swagging Tool Set

model: CT-275

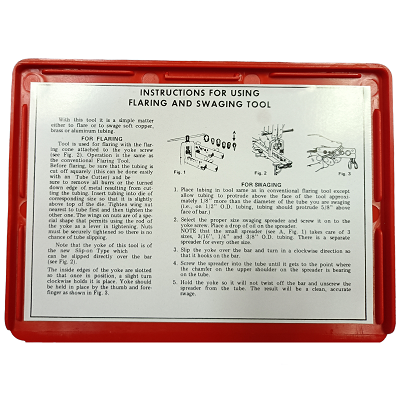

INSTRUCTION FOR USING FLARING AND SWAGGING TOOL

With this tool it is a simple matter either to flare or to swag soft copper, brass or aluminium tubing.

FOR FLARING

Tool is used for flaring with the flaring cone attached to the yoke screw (see fig 2.).

Operation is the same as the conventional Flaring tool.

Before flaring, be sure that the tubing is cut off squarely (this can be done easily with a tube cutter) and be sure to remove all burs or the turned down edge of metal resulting from cutting the tubing. Insert tubing into die of corresponding size so that it is slightly above top of the die. Tighten wing nut nearest to tube first and then tighten the other one. The wings on nuts are of a special shape that permits using the rod of the yoke as a lever in tightening. Nuts must be securely tightened so there is no chance of tube slipping.

Note that the yoke of this tool is of the new slip-on type which can be slipped directly over the bar (see fig. 2).

The inside edges of the yoke are slotted so that once in position, a slight turn clockwise holds it is place. Yoke should be held in place by the thumb and forefinger as shown in Fig. 3.

FOR SWAGGING

Place tubing in tool same as in conventional flaring tool except allow tubing to protrude above the face of the tool approximately 1/8” more than the diameter of the tube you are swagging (ie., on ½” O.D. tubing, tubing should protrude 5/8” above face of bar.)

Select the proper size swagging spreader and screw it on to the yoke screw. Place a drop of oil on the spreader for every other size.

Slip the yoke over the bar and turn in a clockwise direction so that it hooks on the bar.

Screw the spreader into the tube until it gets to the point where the chamfer on the upper shoulder on the tube.

Hold the yoke so it will not twist off the bar and unscrew the spreader from the tube. The result will be a clean, accurate swag.